Packaging has come a long way from simple, functional designs to becoming a canvas for creativity and brand representation. In the realm of innovation, laser-cut boxes have emerged as a game-changer, offering unparalleled possibilities for businesses and individuals looking to make a statement with their packaging.

Evolution of Packaging

In the not-so-distant past, packaging was often viewed as a mere necessity – a means to protect products during transit. Traditional methods involved basic materials and simple designs. However, the evolution of packaging has taken a giant leap forward with the introduction of laser-cutting technology.

Laser cutting, once reserved for industrial applications, has found its way into the packaging industry, revolutionizing the way boxes are designed and manufactured. This shift has allowed for intricate patterns, precise detailing, and a level of customization that was previously unimaginable.

Advantages of Laser Cut Boxes

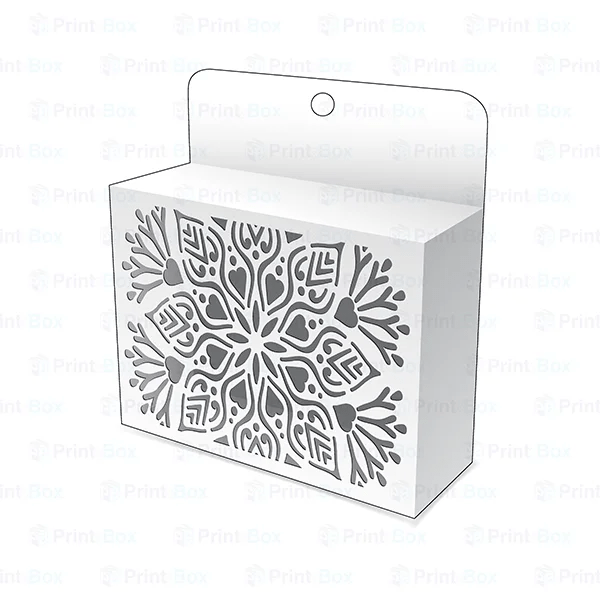

The advantages of opting for laser-cut boxes are multifaceted. Firstly, the precision and intricacy achievable with laser cutting are unmatched. Businesses can now create packaging that truly reflects the essence of their brand or product. The level of customization available allows for unique designs that stand out on the shelves.

From a sustainability standpoint, laser-cut boxes often utilize eco-friendly materials. This not only aligns with the growing environmental consciousness of consumers but also positions brands as responsible and forward-thinking.

Applications in Various Industries

Laser-cut boxes have found applications across diverse industries. In retail, these boxes add a touch of sophistication to product packaging, enhancing the overall customer experience. Wedding and event planners have embraced laser-cut invitations for their elegance and uniqueness. Additionally, artists and craft enthusiasts use laser-cut materials for various creative projects, pushing the boundaries of what is possible.

Choosing the Right Materials

Selecting the right materials is crucial when opting for laser-cut packaging. Materials such as cardboard, wood, and acrylic are commonly used. The choice depends on factors like product type, desired aesthetics, and budget considerations.

Designing Laser Cut Boxes

Creating captivating designs for laser-cut boxes involves the use of specialized software. Designers can experiment with patterns, shapes, and textures to achieve a visually appealing result. It’s essential to keep in mind the balance between intricate details and the practicality of the design for manufacturing and assembly.

Cost-Effectiveness of Laser Cutting

While the initial investment in laser-cutting technology might seem significant, the long-term benefits often outweigh the costs. The precision of laser cutting reduces material wastage, and the customization options can lead to increased brand recognition and customer loyalty.

Popular Laser Cut Box Designs

From geometric patterns to intricate lace-like cutouts, the variety of laser-cut box designs is vast. Businesses can draw inspiration from trending designs or collaborate with designers to create a unique and memorable packaging solution.

Customization for Branding

Branding is a crucial aspect of any business, and laser-cut boxes offer an excellent canvas for showcasing brand identity. Incorporating logos, brand colors, and distinctive design elements ensures that the packaging becomes an extension of the brand itself.

Sustainability in Packaging

As environmental awareness grows, consumers are increasingly favoring sustainable packaging options. Laser-cut materials, particularly when using recyclable or biodegradable substrates, align with these preferences. This not only appeals to eco-conscious consumers but also contributes to a positive brand image.

Challenges and Solutions

Like any technology, laser cutting presents its own set of challenges. Ensuring proper maintenance of equipment, addressing material compatibility issues, and refining the design process are essential for overcoming these challenges. Innovative solutions, such as integrating AI-assisted design tools, are continually improving the efficiency of laser-cutting processes.

Safety Measures in Laser Cutting

Safety is paramount in any manufacturing process involving lasers. Operators and users must adhere to strict safety measures to prevent accidents and ensure a secure working environment. This includes wearing protective gear, implementing machine safety features, and providing thorough training for operators.

Future Trends in Laser Cut Packaging

As technology continues to advance, the future of laser-cut packaging holds exciting possibilities. Emerging trends include the integration of smart packaging features, holographic designs, and even more sustainable materials. Keeping abreast of these trends allows businesses to stay ahead of the curve and maintain a competitive edge.

Case Studies

Several businesses have successfully incorporated laser-cut packaging into their branding strategies. For instance, XYZ Boutique saw a 20% increase in sales after introducing laser-cut gift boxes, showcasing the impact of creative packaging on consumer perception. These case studies serve as inspiration for businesses considering a shift to laser-cut packaging.

Conclusion

In conclusion, laser-cut boxes represent a paradigm shift in the world of packaging. The marriage of precision, customization, and sustainability makes them a powerful tool for businesses looking to make a lasting impression. Embracing this innovative approach not only enhances the visual appeal of products but also aligns with evolving consumer preferences for unique and eco-friendly packaging solutions.

FAQs

- Are laser-cut boxes more expensive than traditional packaging?

- While the initial costs may be higher, the long-term benefits often justify the investment.

- Can laser-cut boxes be used for food packaging?

- Yes, with the right materials and adherence to food safety standards, laser-cut boxes are suitable for food packaging.

- What materials are commonly used for laser-cut boxes?

- Cardboard, wood, and acrylic are among the commonly used materials for laser-cut packaging.

- How can businesses incorporate laser-cut boxes into their branding?

- Businesses can include logos, brand colors, and unique design elements to create a distinct brand identity on their packaging.

- Are there any safety concerns with laser cutting?

- Yes, safety is crucial, and operators must follow strict safety measures to prevent accidents.