Vaccine packaging plays a pivotal role in ensuring the efficacy, safety, and accessibility of vaccines. The significance of robust vaccine packaging solutions becomes increasingly evident as the world grapples with the challenges posed by infectious diseases, such as the recent COVID-19 pandemic. This article delves into the current challenges in vaccine packaging and explores innovative strategies to overcome them.

Introduction

Vaccine packaging encompasses the materials and methods used to safely contain and deliver vaccines to healthcare providers and patients. It serves multiple purposes, including protecting the vaccine from external factors that could compromise its potency, ensuring proper storage conditions, and facilitating efficient distribution networks.

Historical Overview of Vaccine Packaging

The history of vaccine packaging dates back centuries, with early methods relying on rudimentary materials such as glass vials and cork stoppers. Over time, advancements in technology and understanding of microbiology have led to significant improvements in vaccine packaging, including the introduction of sterile packaging techniques and the use of preservatives to enhance shelf life.

Current Challenges in Vaccine Packaging

Temperature Control and Stability

One of the foremost challenges in vaccine packaging is maintaining temperature control throughout the storage and transportation process. Many vaccines are sensitive to temperature fluctuations and can lose their efficacy if exposed to improper conditions. This poses a significant hurdle in regions with limited access to reliable refrigeration systems, where vaccines may be subject to heat exposure or freezing temperatures during transit.

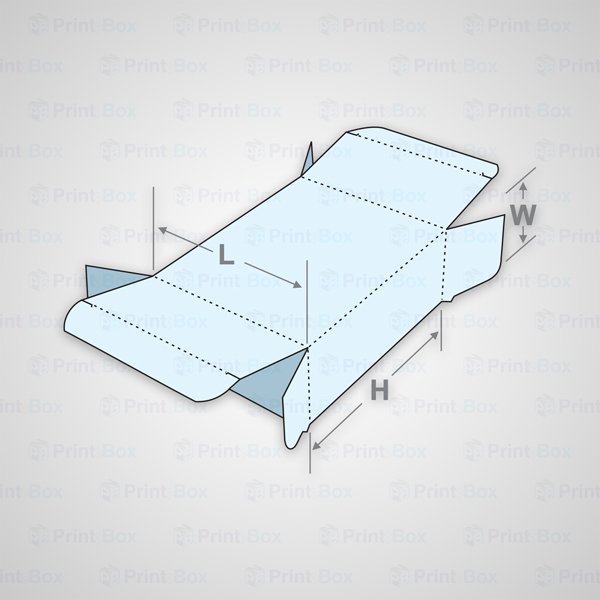

Packaging Materials

The selection of appropriate packaging materials is critical in ensuring the stability and integrity of vaccines. Traditional materials such as glass and plastic have been widely used; however, they may not always provide adequate protection against environmental factors or physical damage. Moreover, concerns regarding the leaching of harmful chemicals from certain plastics have prompted the exploration of alternative biodegradable and recyclable materials.

Safety Concerns

Ensuring the safety of vaccine packaging is paramount to prevent contamination and maintain product quality. Issues such as microbial growth, particulate matter contamination, and improper sterilization techniques can compromise the safety of vaccines, posing risks to public health. Addressing these concerns requires stringent quality control measures and adherence to regulatory guidelines.

Distribution Logistics

Efficient distribution logistics are essential for the timely delivery of vaccines to healthcare facilities and communities worldwide. However, logistical challenges such as inadequate infrastructure, lack of cold chain storage facilities, and transportation bottlenecks can impede the effective distribution of vaccines, particularly in remote or resource-constrained areas.

Technological Innovations Addressing Packaging Challenges

Researchers and manufacturers are actively exploring technological innovations to enhance vaccine packaging solutions in response to the aforementioned challenges.

Smart Packaging Solutions

Smart packaging technologies, such as temperature-sensitive labels and RFID tracking systems, enable real-time monitoring of vaccine storage conditions. These innovations provide valuable insights into temperature deviations and ensure timely interventions to prevent spoilage.

Nanotechnology Applications

Nanotechnology offers promising opportunities for improving vaccine packaging by enhancing stability and prolonging shelf life. Nanostructured materials can provide better protection against environmental stressors and enable the controlled release of vaccine components, thus optimizing efficacy.

Biodegradable Packaging

Developing biodegradable packaging materials offers a sustainable alternative to conventional plastics, reducing environmental impact and waste generation. Biopolymers derived from renewable sources, such as plant-based materials, exhibit favorable properties for vaccine packaging while minimizing ecological footprint.

Regulatory Framework for Vaccine Packaging

Regulatory agencies such as the Food and Drug Administration (FDA) in the United States establish stringent guidelines and standards to ensure the safety and efficacy of vaccine packaging.

FDA Guidelines

The FDA regulates vaccine packaging under strict guidelines, encompassing requirements for materials, manufacturing processes, labeling, and storage conditions. Compliance with these regulations is essential to obtain approval for vaccine products and maintain public trust.

International Standards

In addition to national regulations, international organizations such as the World Health Organization (WHO) and the International Organization for Standardization (ISO) collaborate to establish harmonized standards for vaccine packaging. These standards facilitate global cooperation and promote uniformity in quality assurance practices.

Environmental Impact of Vaccine Packaging

While vaccine packaging is essential for preserving public health, it also contributes to environmental pollution and resource depletion.

Waste Generation

The widespread use of single-use packaging materials generates significant waste, adding to the burden on landfills and incineration facilities. Improper disposal practices further exacerbate environmental degradation and harm ecosystems and human health.

Recycling and Sustainability Initiatives

To mitigate the environmental impact of vaccine packaging, stakeholders are increasingly embracing recycling and sustainability initiatives. This includes promoting recyclable materials, implementing waste reduction strategies, and investing in renewable energy sources for manufacturing processes.

Future Trends in Vaccine Packaging

Looking ahead, several trends, driven by advancements in materials science, technology, and sustainability, are poised to shape the future of vaccine packaging.

Advanced Materials

The emergence of novel materials with enhanced barrier properties and biocompatibility will revolutionize vaccine packaging, enabling greater protection and stability of vaccines while minimizing environmental footprint.

Personalized Packaging Solutions

Advances in personalized medicine and digital health technologies will pave the way for customized vaccine packaging solutions tailored to individual patient needs. This includes personalized dosage forms, convenient packaging formats, and patient-centric labeling.

Conclusion

In conclusion, vaccine packaging faces numerous challenges, from temperature control and safety concerns to environmental sustainability. However, ongoing research and technological innovations offer promising solutions to address these challenges and ensure the availability of safe and effective vaccines for global populations. By prioritizing quality, safety, and sustainability in vaccine packaging practices, stakeholders can contribute to a healthier and more resilient future.

FAQs

- Why is temperature control important in vaccine packaging?

- Temperature control is crucial to maintaining vaccines’ potency and efficacy, as exposure to improper temperatures can lead to degradation and loss of effectiveness.

- What are some examples of innovative packaging technologies used in vaccine packaging?

- Examples include temperature-sensitive labels, RFID tracking systems, and intelligent sensors embedded in packaging materials.

- How do regulatory agencies ensure the safety of vaccine packaging?

- Regulatory agencies such as the FDA establish strict guidelines and standards for vaccine packaging, covering materials, manufacturing processes, and storage conditions.

- What are the environmental implications of traditional vaccine packaging materials?

- Traditional materials such as plastics contribute to environmental pollution and waste generation, highlighting the need for sustainable alternatives.

- What role do international organizations play in setting standards for vaccine packaging?

- International organizations such as the WHO and ISO collaborate to establish harmonized standards for vaccine packaging, promoting global consistency and quality assurance.